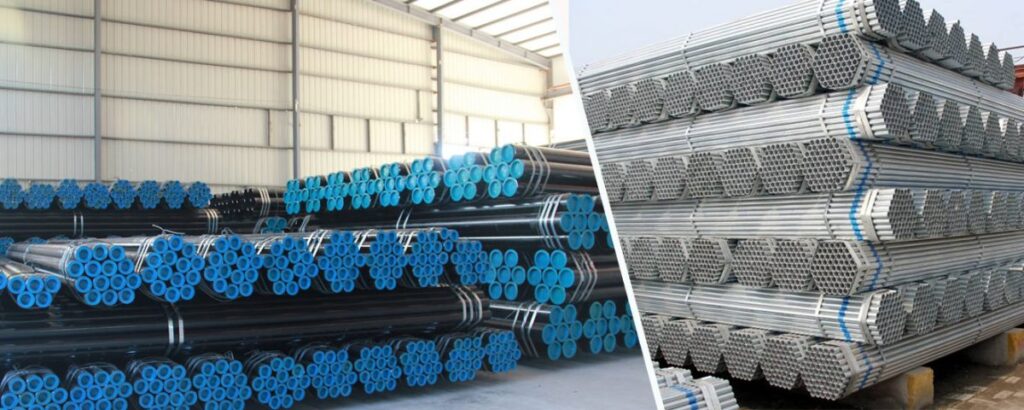

Seamless Pipe Manufacturer & Supplier

home/seamless-pipe

We are equipped with a large volume for annealing a solution in a continuous rolling hearth furnace to produce seamless pipe from the hollow mother pipe. The production line of Victor Metal Industries is examined by numerous customers and other parties, and we have an internal experimental infrastructure. On request, we may also provide double random lengths. The needs of the industry are our top concern at Victor Metal Industries to meet the demands and desires of the industrial sector, we produce these pipes and tubes with additional features and functionality.

Seamless pipes are commonly made by cutting, welding, and bevelling pipe material for a variety of uses. We create and market a range of fabrication and automation solutions as a whole. When designing and building prefabricated structures with digital technologies, we can determine the production size with accuracy.

We are one of the major manufacturers of seamless stainless steel pipes because of the capacity of all 30 Pilger machines that construct stainless steel pipe. With a product portfolio that is the first choice for international project owners, Suraj Limited, a leading EPC contractor and process licensor, has established a solid name for itself in the market.

Specification of Seamless Pipe

| Process Method | Cold Drawn Seamless Pipes, Hot Rolled Stainless Steel Seamless Pipes |

| Stainless Steel Grades | TP304 / TP304L / TP316L / TP321 |

| Standard | ASTM A312, ASTM A249, ASTM A269, ASTM A789 |

| Size | a) O.D.: 6–610mm, W.T: 0.8mm–30mm |

| b) Schedule: 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S,acc. to ANSI B36.19/36.10 | |

| Tube Surface | Annealed, Pickled, Polished, Brush Finish |

| Brand | Metline, Imported |

Available Seamless Pipe Materials

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Duplex Steel

- Super Duplex Steel

- Inconel

- Monel

- Hastelloy

- Titanium

- Aluminum

Drawn-on mandrel construction is how we construct seamless pipes. Another name for it is the cold drawn method. This seamless pipe manufacturing procedure improves the dimensional tolerance of the pipes and helps to give them a smooth interior and exterior. To obtain the necessary mechanical properties, the tubes are heated in chambers.

To guarantee that the products we offer to you are of the greatest caliber, we carry out thorough quality tests. We also use a specific 4-Layer packaging for exports in accordance with optimal packing techniques. The packing process guarantees that the items arrive at their destination in top shape.

Applications of Seamless Pipe

Oil and Gas Industry: They are widely used in oil refineries, pipelines, and petrochemical plants for their superior strength and leak-free connections.

Power Generation: These fittings are essential for power plants, including thermal, nuclear, and renewable energy, for their ability to withstand high temperatures and pressures.

Chemical Processing: Crucial for chemical plants, offering corrosion resistance and ensuring the integrity of the piping system.

Pharmaceutical and Food Processing: Hygienic pipe fittings are utilized in industries that require sanitary connections, such as pharmaceuticals and food processing.

Water and Wastewater Treatment: They are used in water treatment plants, desalination facilities, and wastewater treatment plants for their durability and leak-free performance.

Test Methods

a) Chemical Analysis Test

The method for material chemical analysis is done as per ASTM A751. This is as per API 5L standard section 9.10 subsection one.

b) Tensile Test

Our test Method for material tensile test is done as per ASTM A370. This is as per API 5L standard section 9.10 subsection two

c) Equipment Calibration

This is done within 15 months according to ASTM E4 under API 5L standard section 9.10.2.2

d) Guided Bend Tests

Shall be performed to conform to API 5L standard section 9.10.3 and within subsequent reference

e) Charpy Tests

Shall be performed in accordance with ASTM A370 as per API standard section 9.10.4

f) Other tests

Invalidation of Tests (as Per API 5L 9.11.1/2) , Retests (i) Recheck Analysis API 5L 9.12.1 (ii) Recheck Analysis API 912.2 , Flattening Tests ( API 5L 9.12.3) , Bend Retest (API 5L 9.12.4) , Guided Bend Retest ( API 5L 9.12.5) , Charpy Rest ( API 5L 9.12.6) , Reprocessing ( API 5L 9.13)

Our Products

Contact for any piping solutions

For more details on the products contact us.

Fittings, Flanges, High Nickel Alloy Pipe Fittings & Flanges , Sheets, Plates & Coil, Circles, Rings, Heavy Thickness Blocks, Copper Fittings And Coils, Brass Fittings And Coils, Round, Square, Hex, Flat Bars, Flats, Angle, Channel & Beam, Pipes & Tubes